Table of Contents

Report Description

The market for wafer mounter equipment has been covered under the scope of this report. Wafer mounting is one of the major steps during wafer fabrication. Wafer mounter equipment in the global market is expected to witness strong growth during the forecast period. This is mainly due to the transition towards 3D IC design structures being one of the key factors, which in turn is anticipated to be a major driving factor for the global wafer mounter equipment market.

Wafer mounting is one of the most important stages during the process of die preparation that is required for various semiconductor device fabrications in which the wafer is prepared for IC testing and IC packaging. The wafer is mounted on a plastic tape that is primarily attached with a ring during the wafer mounting process. The process is performed right before the wafer is cut into different separate dies. The function of the adhesive tape is to keep individual dies firmly in their own place during the process of dicing.

Thus, the importance of wafer mounting technique is inevitable during the process of wafer fabrication. This in turn is anticipated to create huge demand for various types of wafer mounting equipment owing to rising demand for thin and ultrathin wafers from different semiconductor equipment manufacturers in the coming years. The market for wafer mounter equipment across the globe bears a proportional relationship with the overall semiconductor industry and is expected to witness stable growth during the forecast period from 2017 to 2025, both in terms of revenue (USD million) and volume (units).

The global wafer mounter equipment market has been segmented on the basis of:

- Type

- Wafer size

- Application

- End user, and

- Region

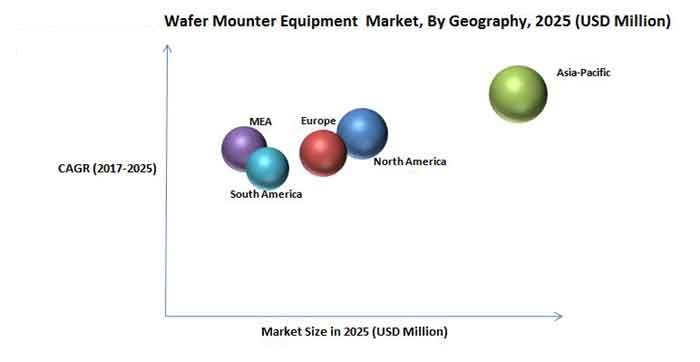

It also provides a cross-sectional study of the global wafer mounter equipment market across broad regional segments such as North America, Europe, Asia-Pacific (APAC), Middle-East & Africa (MEA), and South America under its scope. Due to rising demand for thin and ultrathin wafers from different semiconductor equipment manufacturers, which is predicted to create a huge demand for various types of wafer mounting equipment in coming years, Across the globe, various memory manufacturers and foundries are aiming to make rapid investments in the purchase of new equipment that is in line with the changing semiconductor IC architecture. This reason is subsequently expected to drive the demand for the wafer mounter equipment market worldwide.

Scope of the Report

A complete analysis of market dynamics, which includes the market drivers, restraints, and opportunities, is included within the scope of the report. The market dynamics for the different segments, namely type, application, wafer size, and end user, have been covered separately under the purview of the report. Additionally, the country-level trend for each region has also been covered under the scope of the report. Thus, this report provides an exhaustive study of the global wafer mounter equipment market and also provides a forecast of the market for the period from 2017 to 2025.

Market Dynamics

The increasing application of various semiconductor devices across different emerging applications, including the Internet of Thing (IoT) and Artificial Intelligence (AI), is one of the most important factors anticipated to influence the production of wafers in a positive manner. Thus, wafer mounter equipment, being an indispensible part of a wafer mounter system that is extensively required during the wafer fabrication process, is expected to witness a rapid demand from various wafer manufacturers across the globe during the forecast period from 2017 to 2025. In addition, rising capital spending is also anticipated to create a favourable market for various wafer mounter equipment manufacturers in the near future. After the cyclical period of 2016, the semiconductor industry across the globe is predicted to witness a surge in capital spending. Thus, various memory manufacturers and foundries are aiming to make rapid investments in the purchase of new equipment that is in line with the changing semiconductor IC architecture. Therefore, this is predicted to pave the way for better demand for various wafer mounter equipment during the next eight years.

High-level Analysis Covered in the Report

Under the scope of the report on global wafer mounter equipment market, several high-level analyses have been covered. This includes:

- The product-market trend analysis

- Product life-cycle analysis

- Porter’s five forces analysis, and

- Market attractiveness analysis

Key trends analysis discusses the current and upcoming trends in this market. Product life-cycle analysis analyses the current life-cycle stage of the product in the five wide geographic regions, such as whether the product is approaching maturity in a region or whether it is a new entrant, etc. Porter’s five forces analysis provides insights into the competitive scenario with regards to new entrants, substitutes, buyers, and suppliers. To provide a detailed insight into the global wafer mounter equipment market, attractive analysis has been provided in the report. The market attractiveness analysis details the investment attractiveness by type, application, wafer size, end user, and geography.

The Competitive Profiling

The competitive profiling of the key players in the global wafer mounter equipment market and their business segments has been exhaustively covered under the purview of the study. Moreover, key business strategies adopted by the leading players in the market have also been covered under the scope of the report.

Some Leading Companies in the Wafer Mounter Equipment Market

Some of the major players operating in the global wafer mounter equipment market includes:

- DISCO Corp. (Japan), Tokyo Electron Ltd.(Japan), Lintec Corporation (Japan), Nitto Denko (Japan), Takatori (Japan)

- Advanced Dicing Technologies (Israel)

- Longhill Industries (China)

- Syagrus Systems (The U.S), Technovision (The U.S), Ultron Systems (The U.S) among others.

Report Highlights

- Impeccable insights related to relevant segment of the market.

- In depth analysis of key trends of the market.

- In-depth analysis of the competitive landscape and competitor behavior in the market.

- Major push factors that will influence the growth of the market.

- Growth potential in different segments of the market till 2025.

- Key strategies executed by the market leaders to maintain growth in the market.

- Major restrictive factors of the market.

- Ways to generate new revenue.

- Free customization with maximum flexibility limit.

Wafer Mounter Equipment Market Segmentation Overview

In order to provide a detailed and in-depth analysis of the global wafer mounter equipment market across different regions of the world, including North America, Asia-Pacific, Europe, Middle-East, Africa, and South America, the market has been segmented on the basis of type, application, wafer size, and end user.

Different types of wafer mounter equipment available on the market, including fully automatic mounter equipment, semi-automatic mounter equipment, and manual mounter equipment, are covered within the scope of research.

Moreover, different application segments in which wafer mounter equipment is majorly employed, such as for wafer dicing purposes, for DAF (Die Attached Film), and for wafer protection purposes, among others, are also highlighted in this report.

In addition, demand for various types of wafer mounter equipment from different end users, including memory manufacturers, foundries, and IDMs (Integrated Device Manufacturers), has also been furnished in this report.

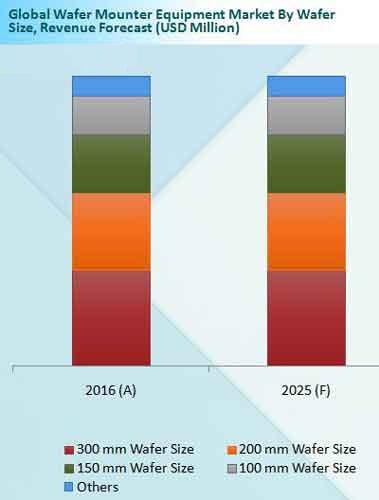

Again, based on different wafer sizes, the market has been classified into 300 mm wafer size, 200 mm wafer size, 150 mm wafer size, and 100 mm wafer size, among others. In addition, cross-sectional analysis of the above mentioned segments among the different regions is also elaborately explained in this report in order to depict the current market situation along with the future expected demand trend of wafer mounter equipment during the forecast period. Among the different types of wafer mounter equipment available in the market, manual wafer mounter equipment held the largest market share both in terms of value and volume in 2016, owing to its low cost and ease of handling, and is anticipated to maintain its lead position throughout the forecast period. However, the demand for manual wafer mounter equipment is anticipated to be increasingly replaced by fully automatic wafer mounter equipment in the coming years as industries are increasingly inclined towards attainment of full automation systems in their manufacturing processes. Moreover, given the rising need to upgrade the reliability and efficiency of the plants, the wafer manufacturers are expected to adopt automatic wafer mounter equipment to automate various processes. The automatic wafer mounter equipment offers various competitive advantages, such as increasing wafer handling frequency, reliability, and throughput, along with eliminating faults due to human errors.

Wafer Mounter Equipment Market: By Type

- Fully Automatic Wafer Mounter Equipment

- Semi-Automatic Wafer Mounter Equipment

- Manual Wafer Mounter Equipment

Wafer Mounter Equipment Market: By Application

- Dicing

- DAF (Die Attached Film)

- Protection (Back Grinding)

- Others

Wafer Mounter Equipment Market: By Wafer Size

- 300 mm Wafer Size

- 200 mm Wafer Size

- 150 mm Wafer Size

- 100 mm Wafer Size

- Other

Wafer Mounter Equipment Market: By End User

- Memory Manufacturers

- Foundries

- IDMs

- Others

Wafer Mounter Equipment Market: By Geography

- North America (U.S., Canada and Mexico)

- Europe (U.K., Germany, France, CIS + Scandinavia and Rest of Europe)

- Asia-Pacific (China, Japan, Taiwan, South Korea and Rest of Asia-Pacific)

- Middle East & Africa (Israel, South Africa and Rest of Middle East & Africa)

- South America (Brazil, and Rest of South America)

Regional Outlook

Geographically, the global wafer mounter equipment industry is anticipated to be majorly driven by the Asia-Pacific region both in terms of revenue generation and growth throughout the forecast period. The presence of a large number of foundries in the Asia-Pacific region, especially in China, South Korea, Japan, and Taiwan, is the primary factor attributed to this region’s high market share and growth trend. In addition, initiatives taken by the existing foundries in this region to construct new wafer fabrication plants in the coming years are also predicted to drive the demand for wafer mounter equipment in this region. In 2016, the wafer mounter equipment market in the Asia-Pacific region was followed by North America in terms of revenue generation.