Table of Contents

Solar Cell Metallization Pastes Market – Introduction

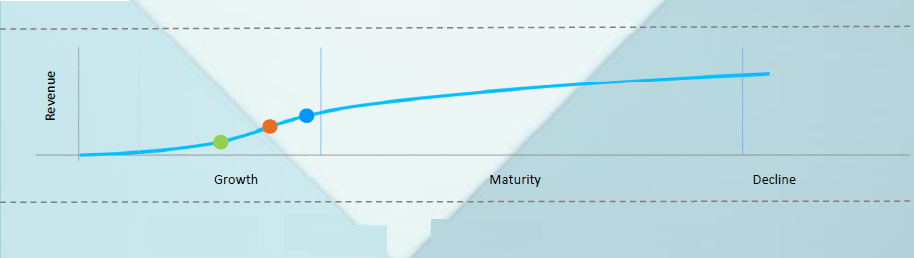

The global solar cell metallization pastes market is expected to grow significantly during the forecast period of 2017 to 2025. The solar cell metallization pastes market is segmented into types, application patterns, end uses, and geography. Solar cell metallization pastes are metallic pastes used for solar cells for conductivity and power output. Solar cell metallization pastes offer significant efficiency gains for multi as well as monocrystalline silicon-based photovoltaic cells. Traditionally, aluminum (Al) and silver (Ag) based metallization pastes are mostly consumed in the solar cell industry. Rising demand for renewable energy based on solar cells and awareness of decreasing loss during converting sunlight into electricity are some of the prime growth drivers for the market. The rising demand for increasing energy yield for photovoltaic cells has acted as a push factor for the application market’s growth for solar cell metallization pastes.

Report Overview

| Aspect | Details |

| The base year of Estimation | 2016 |

| Value Estimation Year | 2017 |

| Forecast Period | 2017 – 2025 |

| Regional Scope | North America, Asia Pacific, Europe, Middle East & Africa (MEA), and Latin America |

| Report Coverage | Technology Analysis, Market Dynamics, Market Trends, Segmentation Overview, and Competitive Landscape of the market. |

Market Segmentation Overview

| Segments | Details |

| By Type | Silver (Ag), aluminum (Al), and others |

| By Application Pattern | Front side metallization and backside metallization |

| By End-Use | P-type solar cell, passivated emitter rear cell (PERC), and others |

| By Region | North America, Asia Pacific, Europe, Middle East & Africa (MEA), and Latin America |

Technology Analysis

Metallization paste can be applied to both the front side and the backside of solar cells. Significant similarities exist between metal paste for solar cells and thick film applications. Solar cell metallization pastes are uniformly dispersed organic and inorganic materials. These pastes are applied onto wafers through screen-printing and other types of deposition methods. Organic materials in the paste serve as temporary carriers, and these materials evaporate during the drying and firing processes. As a result of the process, silver or aluminum gets deposited on the silicon wafer. Glass is also used as a mixture component in the paste. Each component of the paste has a different application. For example, the silver powder offers conductivity, whereas glass helps in the penetration of antireflective layers.

Market Dynamics

Silver, as well as aluminum based metallization pastes, are widely used in the solar cell industry to increase the efficiency of solar cells in terms of higher conductivity and greater yield of energy output. Rising solar cell production has fuelled the demand for metallization pastes across the photovoltaic industry globally. Rising demand for reliable solar solutions across the residential sector, power generation sector, and aerospace and defense sector is fuelling the growth of the solar cell metallization pastes market. Rising applications of silver paste for passivated emitter rear cell (PERC) design solar cells are acting as a midterm push factor for the growth of the market.

In industrial solar cell manufacturing, demand for rear-side tabbing pastes is growing owing to its multiple benefits, such as an increase in durability of the solar cell, and a decrease in the cost of operation of the photovoltaic cell, and rising efficiency of the cell. For similar reasons, the demand for aluminum paste for solar cells has grown significantly in recent years. In order to meet the requirements of solar cell manufacturers, metallization paste producers are expanding the applications of their product offerings. For example, in 2017, DuPont Photovoltaic Solutions developed “Solamet” metallization pastes for advanced screen printing that offer excellent fine line printing, better electrical conductance, and high solderability. Such new product innovations are expanding the application market for solar cell metallization paste.

The growth prospect of the solar cell metallization pastes market has been slightly dented by the volatility of prices in the metal commodity market and the lack of penetration of the latest technology in the Asia Pacific region. In the coming years, the application of low-temperature processing paste in the solar cell manufacturing industry is expected to drive the growth of the market.

Market Trends

In recent years, demand for aluminum or silver-based metallization paste has increased significantly, caused by rising awareness of efficiency in terms of the energy output of solar cells, rising demand for solar project installation in the residential sector, and government regulations supporting renewable energy usage. On the other hand, the growing demand for solar cells in the industrial sector globally has created an opportunity for solar cell metallization pastes producers. Product innovation remains the prime strategy for leading solar cell metallization paste producers to achieve a competitive advantage and open up new revenue streams.

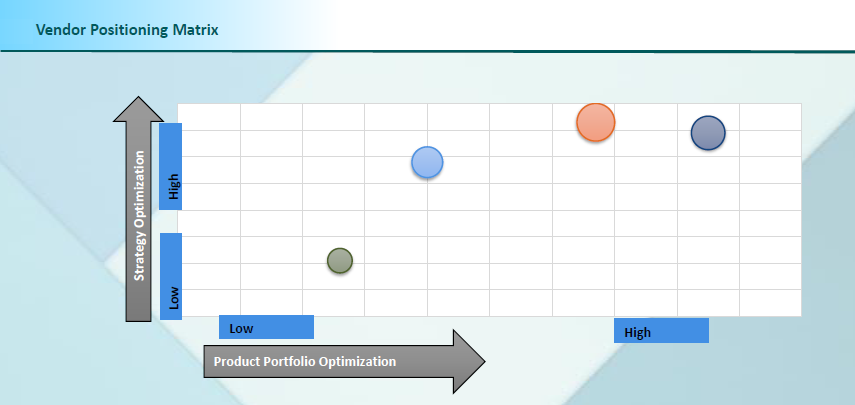

In terms of market structure, the solar cell metallization pastes market is fragmented in nature due to the presence of large numbers of players in the market.

Segmentation Overview

By Type

In terms of types, the market has been segmented as silver (Ag), aluminum (Al), and others.

- Silver (Ag),

- aluminum (Al), and others

By Application Pattern

In terms of application pattern, the solar cell metallization pastes market has been divided into front side metallization and back side metallization.

- Front side metallization, and

- Backside metallization

By End-Use

In terms of end-use, the market has been further segmented into. P-type solar cell, passivated emitter rear cell (PERC), and others. In terms of revenue share, P-type solar cells held the largest share of the end-use market for solar cell metallization pastes.

- The P-type solar cell,

- Passivated emitter rear cell (PERC) and others

By Regions

The geographical segmentation for the global solar cell metallization pastes market includes North America, Asia Pacific, Europe, Middle East & Africa (MEA), and Latin America. In terms of both revenue and volume, North America is one of the fastest-growing markets due to the deep penetration of the photovoltaic industry, rising demand for high-performance solar cells, and supportive government regulations for the usage of solar energy. During the forecast period, demand for solar cell metallization paste in Asia-Pacific is estimated to grow owing to the development of the renewable energy sector.

- North America,

- The Asia Pacific,

- Europe,

- The Middle East & Africa (MEA), and

- Latin America

Competitive Landscape

Leading players operating in the solar cell metallization pastes market are DuPont (The U.S.), Heraeus Group (Germany), Indium Corporation (The U.S.), and AG PRO Technology (Taiwan) among others. Most of these companies focus on investing financial and non-financial resources to develop new products and tap the market opportunity.

Conclusion

Considering the dynamic business scenario, rising demand for solar cells in different application markets, and the expansion of the solar energy sector, it is expected that the market will grow at a stable rate during the forecast period of 2017 to 2025. All these factors are estimated to contribute to the overall growth of the market in the coming years.